Electric Actuators for Motion Simulators & Entertainment

EDrive Actuators Inc. offers products ideal for motion control systems in the simulation, arts and entertainment industry. Applications such as animatronics, motion simulators, and theater staging moves require machines that provide smooth and continuous motion to create an illusion appropriate to the experience, with the benefits of low maintenance and long life. EDrive offers electric linear actuators that provide more accuracy and repeatability, clean, quiet and efficient energy, and compatibility with any motor. EDrive can help you find solutions to improve operations and minimize costs.

The choice of EDrive Actuators in combination with the advantages of today’s precision motion control and servo technologies makes possible multi-degree moves of freedom. Eliminating the past technologies of hydraulics and pneumatic with their inherent size, noise production, and maintenance needs.

Motion Simulation applications that utilize EDrive electric linear actuators include:

- Flight Simulators

- Heavy Equipment Simulators

- Space Shuttle Simulators

- Interactive Ride Simulators

- Animatronics

- Theater Set Staging

- Camera sliders in film production

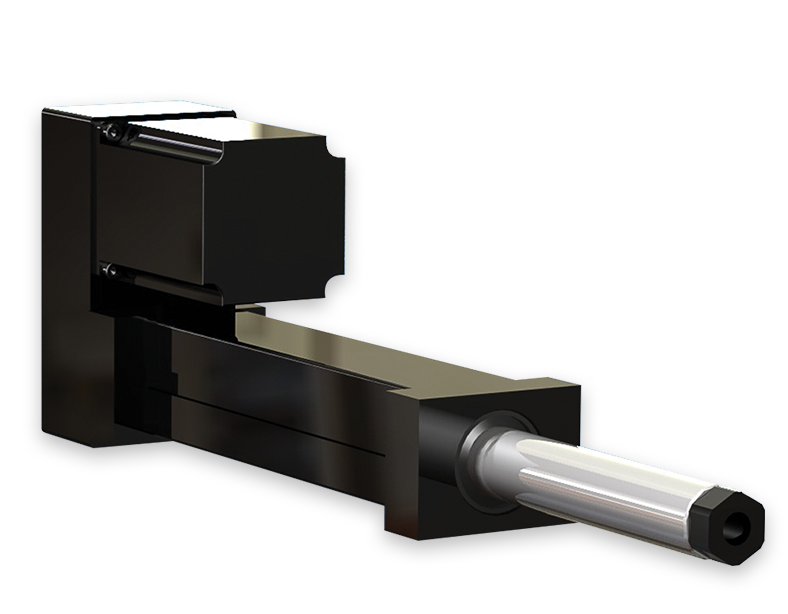

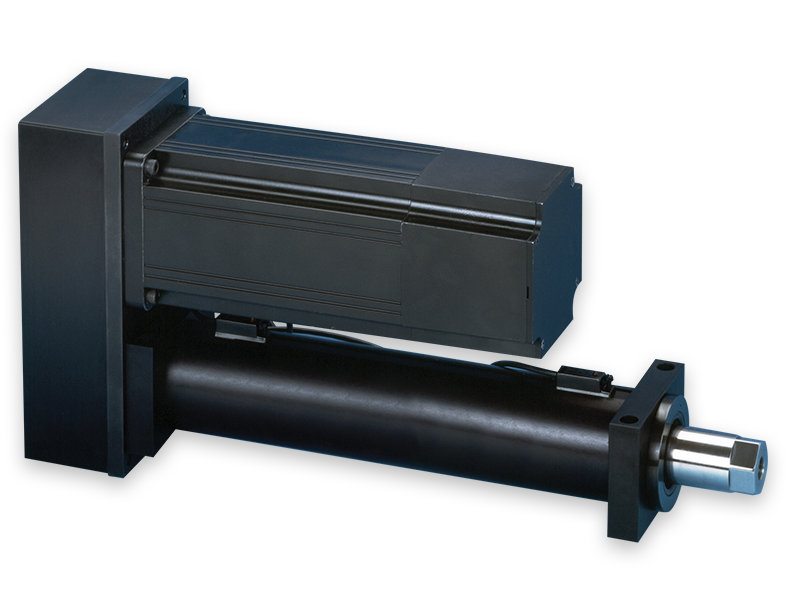

Product Features:

- Flexible motor options

- Sealed chamber design

- High capacity precision ball screw

- Rugged piston, anti-rotation feature

- Low maintenance

- Long life

- Customizable

- Cost-effective

Founded in 1980, EDrive pioneered the evolution of precision electromechanical actuators with our first patented design. Over the years our business has grown based on our philosophy of design flexibility and rapid response to our customers’ requests. While we offer “standardized” product lines we regularly customize based on specific needs.

While other actuator designs force a particular motor decision, EDrive linear actuators are designed to suit virtually any motor, gearbox, or gear reducers the customer chooses to use. In-line as well as parallel offset configurations are standard with 1:1 and 2:1 synchronous gearbelt ratios available.

EDrive customers enjoy an unsurpassed commitment to superior quality, integrity, and customer service. Our experienced staff provides technical support as needed to assist in specifying the most appropriate solutions. Whether you need a standard product or a fully customized actuator EDrive is your answer.